In the necktie procurement process, you must have encountered the following problems: you designed a beautiful necktie. You finally found a supplier through unremitting efforts and got an initial quotation. Later, you optimize your project: such as stunning graphics, high-end packaging, bright logo. As your design requirements change, the quotes you get are constantly evolving. Although you think the final price is acceptable, you can’t help but wonder: why are these additional costs incurred, are these extra costs reasonable, and do design changes like mine need to incur additional charges?

My answer is: that some design changes cost extra, but some don’t.

The underlying logic that affects the purchase price of neckties

When a change in your necktie purchasing program, please consider whether your change meets the following terms:

u Your change adds the purchase cost of raw materials or auxiliary materials.

u Your change adds extra work for workers.

u Your change reduces the utilization rate of fabrics.

u Your change affects the production process.

u Your change increases the difficulty of production and leads to an increase in the defective rate.

The above is the underlying logic that affects the price of the tie. If you have mastered the basic structure of relations and the production process, I believe you can apply the above terms to analyze and solve your problems.

Check out our YouTube channel for the tie production process

Check out our article – The Construction of a Tie

Check out our article - How produces handmade jacquard neckties in batches

Factors that affect the price of a necktie

Analyze common causes that affect necktie prices and match the underlying logic. I hope it can help you!

1. Types of neckties -underlying logic 1, 4, 5

Different types of neckties mean separate accessories purchase, production processes, and defective rates.

According to the different ways of wearing, we divide neckties into classic neckties, zipper neckties, buckle neckties, and rubber band neckties.

From left to right: Classic necktie, clip necktie, rubber band necktie, zipper necktie

1. Material – underlying logic 1,5

Material is the main factor affecting the price of ties, and its influence accounts for more than 60%.

1. The purchase price of raw materials of different materials varies greatly. The mulberry silk and wool are much higher than cotton, recycled fiber, and polyester.

Therefore, when the material of the tie structure, such as the tie fabric, inner lining, logo, and silk lining, is different, the price of the tie will vary greatly.

2. The physical properties of raw materials of different materials are different, affecting the production difficulty of tie fabrics.

2. Fabric – underlying logic 1, 2, 4

Different fabrics have different production processes, so using different types of fabrics will affect the purchase price of the tie.

There are several standard tie fabrics:

1. Jacquard fabric

Jacquard fabrics are woven into patterns with colored yarns. You can use custom yarn or existing yarn to produce your Jacquard fabrics. When using custom yarn, please note that the single-color yarn need reaches 20 kg. Because when the yarn is under 20kg, the dyehouse will charge extra.

2. Screen printing fabric

If you want to purchase neckties made of screen-printed fabric, the number of necktie design colors will affect buying the price. When the necktie’s colors are small but the order quantity is large, the screen printing can reduce the purchasing necktie cost.

3. Digitally printed fabrics

The most significant difference between digital printing and screen printing is that digital printing does not need to change the printing plate. In this way, when the necktie design has many colors, but the order quantity is small, it is more affordable to use digital printing.

From left to right: Jacquard fabric, Screen printing fabric, Digitally printed fabrics

1. Necktie craft – underlying logic 4

We have two ways when the necktie sews: machine or hand sewing.

Hand sewing necktie is more complicated, and the quality is better.

2. Customized projects - underlying logic 1, 3, 4, 5

To make your necktie unique, you will likely use some custom items.

3. Logo label

Sewing an extra logo label under the necktie Keeper loop will increase the work for the worker, and we need to purchase additional accessories.

4. Tipping

There are three types of tipping: Decorative-tipping, Self-tipping, and Logo-tipping (for details about their differences, please see the article – The Necktie Structure Anatomy), and their processing processes are very different.

Decorative-tipping: We buy fabrics available in the market, then cut and make them. The production cost of these fabrics is lower than our jacquard fabrics.

Self-tipping: we cut Self-tapping and other necktie fabrics together and then make; it will Increase the necktie fabric.

Logo-tipping: Compared with Self-tipping, the fabric in Logo-tipping must be woven and cut separately. It will add a lot of extra work to our workers.

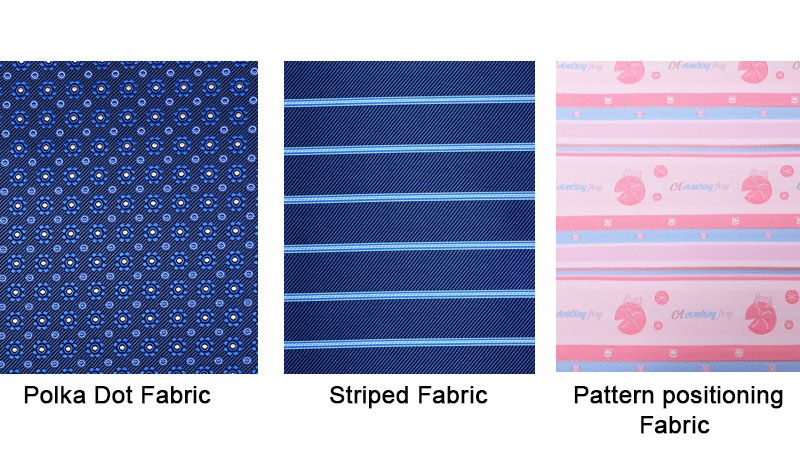

5. Pattern

Different patterns of neckties will affect the fabric utilization and defective rate of neckties.

The effect of pattern on the use rate of fabric:

Irregular patterns: such as polka dots, plaids, flowers, etc., there is no fixed arrangement of designs, you can cut in two directions of 45 degrees or 135 degrees, and there will be the same pattern after cutting. Such patterned fabrics have the highest utilization rate.

Specific Orientation Pattern: if a necktie has a Pattern design with a particular orientation, such as a striped necktie. We can only cut the fabric in the direction of 45 degrees to ensure that the pattern of the tie fabric after cutting is consistent. Such restrictions will reduce fabric utilization.

Fixed Position Pattern: If the necktie design has a pattern in a fixed position. We can only cut the fabric in one direction while keeping the pattern in the correct place. It will increase the difficulty of fabric cutting and, at the same time, reduce the utilization rate of fabrics.

Pattern affects the defective rate of finished products

A complex pattern necktie or plain color necktie design will increase the defective rate. Intricate patterns are more difficult to produce, and simple color neckties are more likely to find fabric defects, all of these reasons increase the defect rate.

6. Necktie size – underlying logic 2

We can customize neckties in various sizes (length, width); the larger the size, the more the fabric used, which means the more significant size necktie has more raw material costs.

We can customize neckties in various sizes (length, width); the larger the size, the more the fabric used, which means the more significant size necktie has more raw material costs.

7. Purchase quantity – underlying logic 2

The larger quantity of ties purchased, the shorter the average production time, and will lower the purchase price.

In the production process of neckties, some process production time has nothing to do with the number of neckties; It is a fixed time. At this time, more quantity can reduce the average production time of ties, such as necktie design, necktie color matching, yarn dyeing, and other processes.

In some production processes, more quantity can significantly improve the efficiency of employees, thus lowering the average production time of the necktie. Such as fabric weaving, necktie sewing, and necktie fabric cutting.

Left: Skinny Tie Right: Classic Tie

8. Packaging - underlying logic 1, 2

We can provide customers with various retail packaging, but their purchase price is not the same; more advanced packaging means a higher price, and our workers also need to spend extra packaging time.

9. Additional items – underlying logic 1, 2

Sometimes customers will ask to add extra accessories to the tie: such as hang tags, hooks, stickers, etc., which will increase the purchasing cost and worker’s packing time.

Post time: Aug-11-2022