The definition of jacquard fabric

Jacquard fabric weaving by machine using two or more colored yarns directly weaves complex patterns into the fabric, and the produced cloth has colorful patterns or designs. Jacquard fabric is different from the production process of printed fabrics, which involves weaving first, and then the logo is added.

History of jacquard fabrics

The predecessor of jacquard fabric

The predecessor of jacquard fabric is Brocade, a silk fabric that originated in the Zhou Dynasty of China (10th to 2nd centuries before the park), with colorful patterns and mature skills. During this period, the production of silk fabrics was kept secret by the Chinese, and there was no public knowledge. In the Han Dynasty (95 years in the park), the Chinese Brocade introduces Persia (now Iran) and Daqin (ancient Roman Empire) through the Silk Road.

Han Brocade: Five stars out of the east to benefit China

Byzantine historians have found that from the 4th to the 6th centuries, tapestry production in silk has been absent, with linen and wool being the main fabrics. It was in the 6th century that a pair of monks brought the secret of sericulture -- silk production -- to the Byzantine emperor. As a result, Western cultures learned how to breed, raise and feed silkworms. Since then, Byzantium became the largest and most central producer in the Western world, producing a variety of silk patterns, including brocades, damasks, brocatelles, and tapestry-like fabrics.

During the Renaissance, the complexity of Italian silk fabric decoration increased (said to have improved silk looms), and the complexity and high quality of luxurious silk fabrics made Italy the most important and finest silk fabric manufacturer in Europe.

The invention of the jacquard loom

Before the invention of the Jacquard loom, Brocade was time-consuming to produce because of the intricate fabric decoration. As a result, these fabrics were costly and only available to the nobility and the wealthy.

In 1804 Joseph Marie Jacquard invented the 'Jacquard machine,' a loom-mounted device that simplified the manufacture of intricately patterned textiles such as Brocade, damask, and matelassé. A "chain of cards controls the machine." many punched cards are laced together into a continuous sequence. Multiple holes are punched on each card, with one complete card corresponding to one design row. This mechanism is probably one of the most critical weaving innovations, as Jacquard shedding made possible the automatic production of unlimited varieties of complex pattern weaving.

The Jacquard loom's invention has significantly contributed to the textile industry. The Jacquard process and the necessary loom attachment are named after their inventor. The term 'jacquard' is not specific or limited to any particular loom but refers to an additional control mechanism that automates the pattern. The fabrics produced by this type of loom can be called 'jacquard fabrics. The invention of the jacquard machine significantly increased the output of jacquard fabrics. Since then, jacquard fabrics have approached the lives of ordinary people.

Jacquard fabrics today

Jacquard looms have changed dramatically over the years. With the invention of the computer, the Jacquard loom moved away from using a series of punched cards. In contrast, Jacquard looms operate by computer programs. These advanced looms are called computerized Jacquard looms. The designer only needs to complete the fabric pattern design through the software and formulate the corresponding loom operation program through the computer. The computer jacquard machine can finish the production. People no longer need to make a complex set of punched cards for each design, significantly reducing the need for manual input and making the jacquard fabric weaving process more efficient and cost-effective.

The production process of jacquard fabric

Design & Programming

When we obtain a fabric design, we first need to convert it into a design file that the computer jacquard loom can recognize and then edit the program file to control the work of the computer jacquard machine to complete the fabric production.

Color matching

To produce the fabric as designed, you must use the correct color yarns for fabric production. So our colorist needs to select some yarns that match the design color from thousands of threads and then compare these similar colors with the design color one by one until the threads that best fit the design color is selected ——Record the corresponding yarn number. This process takes patience and experience.

Yarn preparation

According to the yarn number provided by the colorist, our warehouse manager can quickly find the corresponding Yarn. If the stock quantity is insufficient, we can also promptly purchase or customize the required Yarn. To ensure the fabrics produced in the same batch have no color difference. When preparing the Yarn, we choose the Yarn made in the same batch for each color. If the number of yarns in a batch is insufficient, we will re-purchase a batch of Yarn. When the fabric produces, we use all the newly purchased batches of Yarn, not mixing two batches of Yarn for production.

Jacquard fabric weaving

When all the yarns are ready, the yarns will connect to the jacquard machine for production, and the yarns of different colors will be connected in a specific order. After importing the running program file, the computerized jacquard machine will complete the designed fabric production.

Jacquard fabric treatment

After the fabric is woven, it needs to be treated by physical and chemical methods to improve its softness, abrasion resistance, water resistance, color fastness, and other properties of the fabric.

Jacquard Fabric Inspection

Jacquard Fabric Inspection After the post-processing of the fabric, all the production steps are complete. But if the fabric needs delivery to customers, the final inspection of the fabric is also required to ensure:

- The fabric is flat without creases.

- The fabric is no weft oblique.

- the color is the same as the original.

- The pattern size correct

The characteristics of jacquard fabric

Advantages of jacquard fabric

1. The style of the jacquard fabric is novel and beautiful, and its handle is uneven; 2. Jacquard fabrics are very rich in colors. Different patterns can be woven according to various base fabrics, forming different color contrasts. Everyone can find their favorite styles and designs. 3. Jacquard fabric is easy to take care of, and it is very comfortable to wear in daily life, and it also has the characteristics of lightness, softness, and breathability. 4. Unlike printed and stamped designs, jacquard fabric weave patterns won't fade or fray your clothes.

Disadvantages of jacquard fabric

1. Due to the complex design of some jacquard fabrics, the weft density of the fabric is very high, which will reduce the air permeability of the fabric. 2. The design and production of jacquard fabrics are relatively complicated, and the price is relatively high among fabrics of the same material.

Classification of jacquard fabrics

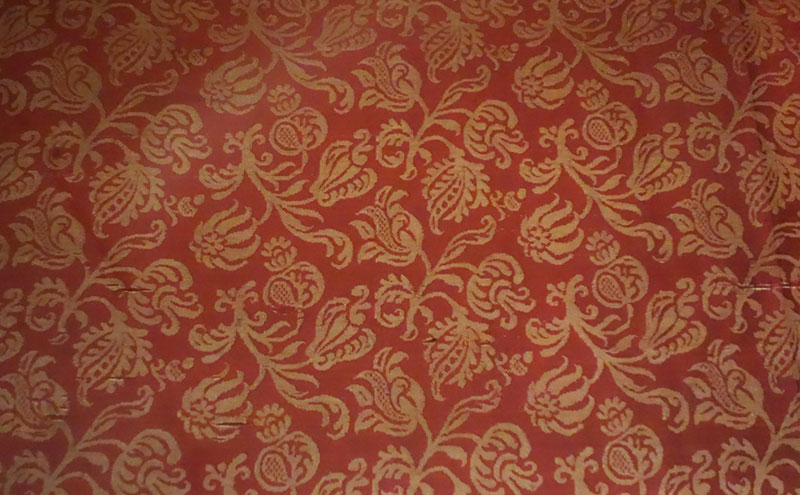

Brocade

Brocade only has a pattern on one side, and the other side does not have a pattern. Brocade is versatile: ·1. Tablecloths. Brocade is excellent for table sets, such as napkins, tablecloths, and tablecloths. Brocade is decorative yet durable and able to withstand everyday use ·2. Clothing. Brocade is excellent for making clothes, such as trim jackets or evening gowns. While heavy fabrics don't have the same drape as other lightweight fabrics, the sturdiness creates a structured silhouette. ·3. Accessories. Brocade is also famous for fashion accessories such as scarves and handbags. Beautiful patterns and dense fabrics make a glamorous look for statement pieces. ·4. Home decoration. Brocade cades have become a home decor staple for their captivating designs. Brocade durability makes it ideal for upholstery and drapes.

Brocatelle

Brocatelle is similar to Brocade in that it has a pattern on one side, not the other. This fabric typically has a more intricate design than Brocade, which has a unique raised, puffed surface. Brocatelle is generally heavier and more durable than Brocade. Brocatelle is usually used for custom and advanced clothing, such as suits, dresses, etc.

Damask

Damask

Damask designs characterize by the base and pattern colors being reverse front to back. Damask is usually contrasting and made with satin threads for a smooth feel. The final product is a reversible luxury fabric material that is versatile. Damask fabric is commonly used and produced in Dresses, Skirts, Fancy Jackets, and Coats.

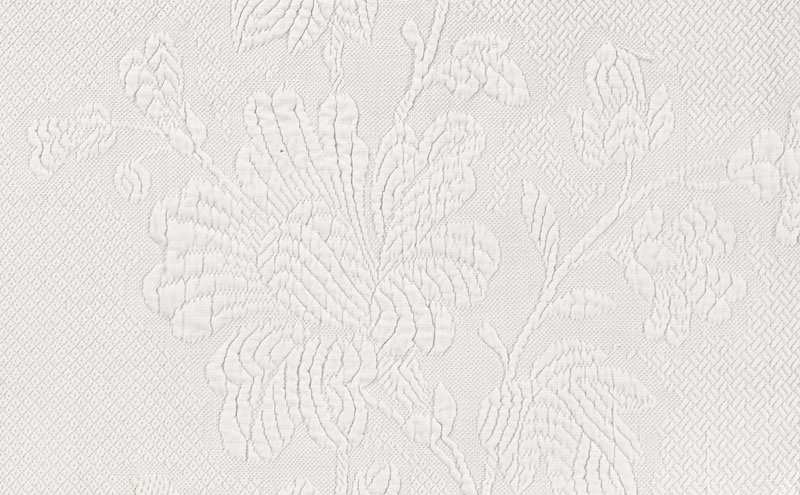

Matelassé

Matelassé (also known as double cloth) is a French-inspired weaving technique that gives the fabric a quilted or padded look. Many quilted fabrics can be realized on a jacquard loom and designed to mimic the style of hand sewing or quilting. Matelassé fabrics are suitable for decorative covers, throw pillows, bedding, quilt covers, duvets, and pillowcases. It is also widely used in crib bedding and children's bedding.

Tapestry

In modern terminology, "Tapestry" refers to a fabric woven on a jacquard loom to mimic historic tapestries. "Tapestry" is a very imprecise term, but it describes a heavy fabric with an intricate multi-colored weave. Tapestry also has the opposite color on the back (for example, a fabric with green leaves on a red ground will have a red leaf back on the green ground) but is thicker, stiffer, and heavier than a damask. Tapestry is usually woven with a thicker yarn than Brocade or Damask. Tapestry For home decoration: sofa, pillow, and stool fabric.

Cloque

Cloque fabric has a raised weave pattern and a pleated or quilted look. The surface is composed of irregularly raised small figures formed by the weaving structure. This jacquard fabric is made differently than other jacquard fabrics in that it is made through a shrinking process. The natural fibers in the fabric shrink during production, causing the material to become covered in blister-like bumps. Cloque gowns and fancy dresses commonly used for various occasions and events are designed in this fabric and are very formal and elegant. It is elegant and exudes a sophistication that no other material can match.

Post time: Feb-17-2023